Energy transition is happening now and at ALTO we know very well and we want to be part of the change.

We developed and implemented advanced dimensional inspection solution for wind farm on-shore and of shore.

Our metrology solution include survey of mono-pile transition pieces flanges and virtual assembly to make sure each part fits properly including the J-tube.

ALTO has a extensive experience in other energy sector like hydro or nuclear power plant, is not time to use our know-how and facilitate technology transition into the new renuawable challenge

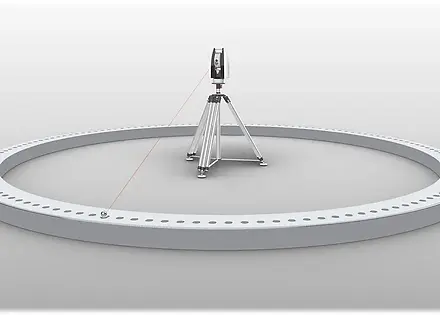

During monopile and jacket fabrication, particular attention should be addressed to can ovality and assembly straightness. The survey is performed with a laser tracker, not only because of the accuracy but mainly for the fast acquisition. All the points of a can can be measured in a few minutes, and a 3D report and dimensional analysis can be done on-site or later in the office. The data can be used anytime for a virtual assembly exercise.

The transition piece is a fundamental element that requires accurate surveying, which can be performed with a laser tracker or photogrammetry. Disto-meter or level laser devices are no longer sufficient as they are slow in acquisition and prone to human error that could impact measurements. Utilizing laser trackers or photogrammetry ensures rapid and fully traceable measurements, eliminating human error.

BCD, BHD, ovality, flatness, bolt hole orientation, and flange tilt are measured and promptly reported in a 3D report

ALTO has developed a unique combined solution using laser tracker and photogrammetry to measure the transition piece bolt hole (TP-BCD) without removing the cover. Our innovative mathematical solution enables PCD inspection without cover removal, whether during bolt tightening or at any stage. The measurement can be conducted by the client or any supplier, and ALTO can remotely run the algorithm and provide a comprehensive report on the flange and PCD condition without requiring direct measurements.

At ALTO, we perform dimensional inspection surveys using advanced technology and software. All the measurements are 3D digitalized, and a virtual assembly simulation can be generated as a result of the study.

Multiple elements of the same assembly are measured and digitized at different moments and places, and then virtually assembled to predict potential misalignments, gaps, or collisions that need to be rectified before the physical assembly takes place